ISO 2768 - General Tolerances Package ISO 2768 - General Tolerances Package. The ISO 2768 - General Tolerances Package provides the permissible deviations of angular and linear dimensions applicable to broken and non broken edges. The permissible deviations are defined to fine, medium, coarse and very coarse tolerance classes. Kurt, if you're asking that SW shows tolerance for each dimension according to 2768 then you're missing the point of 2768. These two standards, ISO 2768-1 and ISO 2768-2 are general tolerancing specifications so you don't have to show dimensions on your drawings.

I have some drawings from Germany that use the DIN 2768 tolerances and I am having trouble understanding it correctly. I do not have a full copy of the DIN but I do have some notes and a brief discription of how the tolerances are supposed to work but I still dont quite understand it.

The parts are shafts and couplings and have to fit bearings so I know some of the tolerances are going to be plus and some are minus. Could anyone offer a simpler explaination of what I am seeing.

One of the external shafts has a f9 while most of the other shafts have a h9 or h6. A keyway has a N9 and the internal keyway has a j59. One of the internal bores has a M6. Most of the tolerances use lower case but some are upper case, I dont know if that makes a difference or not.

Anyone know of a source for a simpler explaination of these that is in english?

Charles

Iso 2768 Mk Standard Tolerance

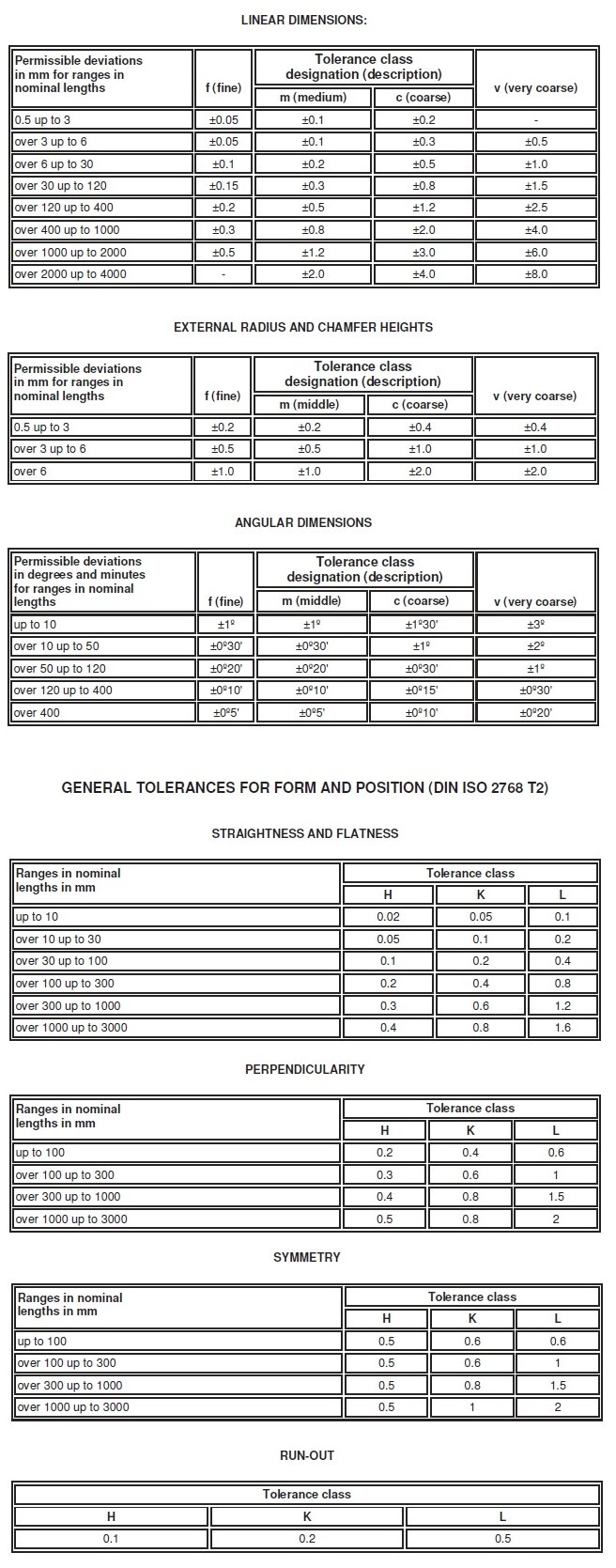

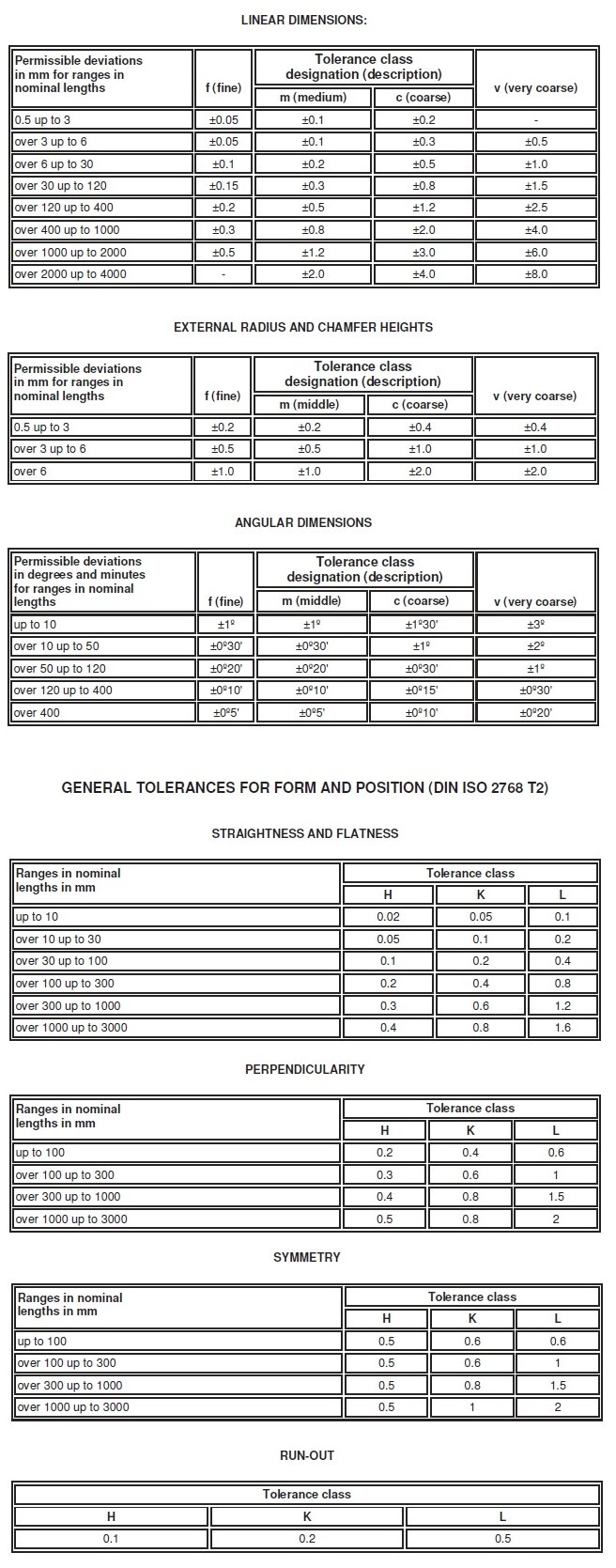

General ISO Geometrical Tolerances Per. ISO 2768 | The following are general geometrical tolerances per. ISO 2768 for the following: - Linear Dimensions

- External Radius and Chamfer Heights

- Straightness and Flatness

- Perpendicularity

- Symmetry

- Runout

Related Mechanical Tolerance Design Data Variations on dimensions without tolerance values are according to ' ISO 2768'. All tolerance limits are given in mm. ISO 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for mechanical tolerances. ISO 2768 is mainly for parts that are manufactured by way of machining or removal of materials. Linear Dimensions: | Permissible deviations in mm for ranges in nominal lengths | f (fine) | Tolerance class designation (description) | v (very coarse) | | m (medium) | c (coarse) | | 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | - |

|---|

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 | | over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 | | over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 | | over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 | | over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 | | over 1000 up to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 | | over 2000 up to 4000 | - | ±2.0 | ±4.0 | ±8.0 |

|---|

External Radius and Chamfer Heights | Permissible deviations in mm for ranges in nominal lengths | f (fine) | Tolerance class designation (description) | v (very coarse) | | m (middle) | c (coarse) | | 0.5 up to 3 | ±0.2 | ±0.2 | ±0.4 | ±0.4 | | over 3 up to 6 | ±0.5 | ±0.5 | ±1.0 | ±1.0 | | over 6 | ±1.0 | ±1.0 | ±2.0 | ±2.0 |

Angular Dimensions | Permissible deviations in degrees and minutes for ranges in nominal lengths | f (fine) | Tolerance class designation (description) | v (very coarse) | | m (middle) | c (coarse) | | up to 10 | ±1º | ±1º | ±1º30' | ±3º | | over 10 up to 50 | ±0º30' | ±0º30' | ±1º | ±2º | | over 50 up to 120 | ±0º20' | ±0º20' | ±0º30' | ±1º | | over 120 up to 400 | ±0º10' | ±0º10' | ±0º15' | ±0º30' | | over 400 | ±0º5' | ±0º5' | ±0º10' | ±0º20' |

Straightness and Flatness | Ranges in nominal lengths in mm | Tolerance class | | H | K | L | | up to 10 | 0.02 | 0.05 | 0.1 | | over 10 up to 30 | 0.05 | 0.1 | 0.2 | | over 30 up to 100 | 0.1 | 0.2 | 0.4 | | over 100 up to 300 | 0.2 | 0.4 | 0.8 | | over 300 up to 1000 | 0.3 | 0.6 | 1.2 | | over 1000 up to 3000 | 0.4 | 0.8 | 1.6 |

Perpendicularity | Ranges in nominal lengths in mm | Tolerance class | | H | K | L | | up to 100 | 0.2 | 0.4 | 0.6 | | over 100 up to 300 | 0.3 | 0.6 | 1 | | over 300 up to 1000 | 0.4 | 0.8 | 1.5 | | over 1000 up to 3000 | 0.5 | 0.8 | 2 |

Symmetry (Position for ISO G&T Standard not-ASME or ANSI GD&T) | Ranges in nominal lengths in mm | Tolerance class | | H | K | L | | up to 100 | 0.5 | 0.6 | 0.6 | | over 100 up to 300 | 0.5 | 0.6 | 1 | | over 300 up to 1000 | 0.5 | 0.8 | 1.5 | | over 1000 up to 3000 | 0.5 | 1 | 2 |

Run-Out | Tolerance class | | H | K | L | | 0.1 | 0.2 | 0.5 |

Related Resources: - Online GD&T Fundamentals

© Copyright 2000 - 2019, by Engineers Edge, LLC www.engineersedge.com

All rights reserved

Disclaimer | Feedback

Advertising | Contact | Privacy Policy Date/Time:

|

| Home

Engineering Book Store

Engineering Forum

Excel App. Downloads

Online Books & Manuals

Engineering News

Engineering Videos

Engineering Calculators

Engineering Toolbox

GD&T Training Geometric Dimensioning Tolerancing

DFM DFA Training

Training Online Engineering

Advertising Center

|

|

|